Ultimate Guide to Warehousing: Functions, Types, Advantages

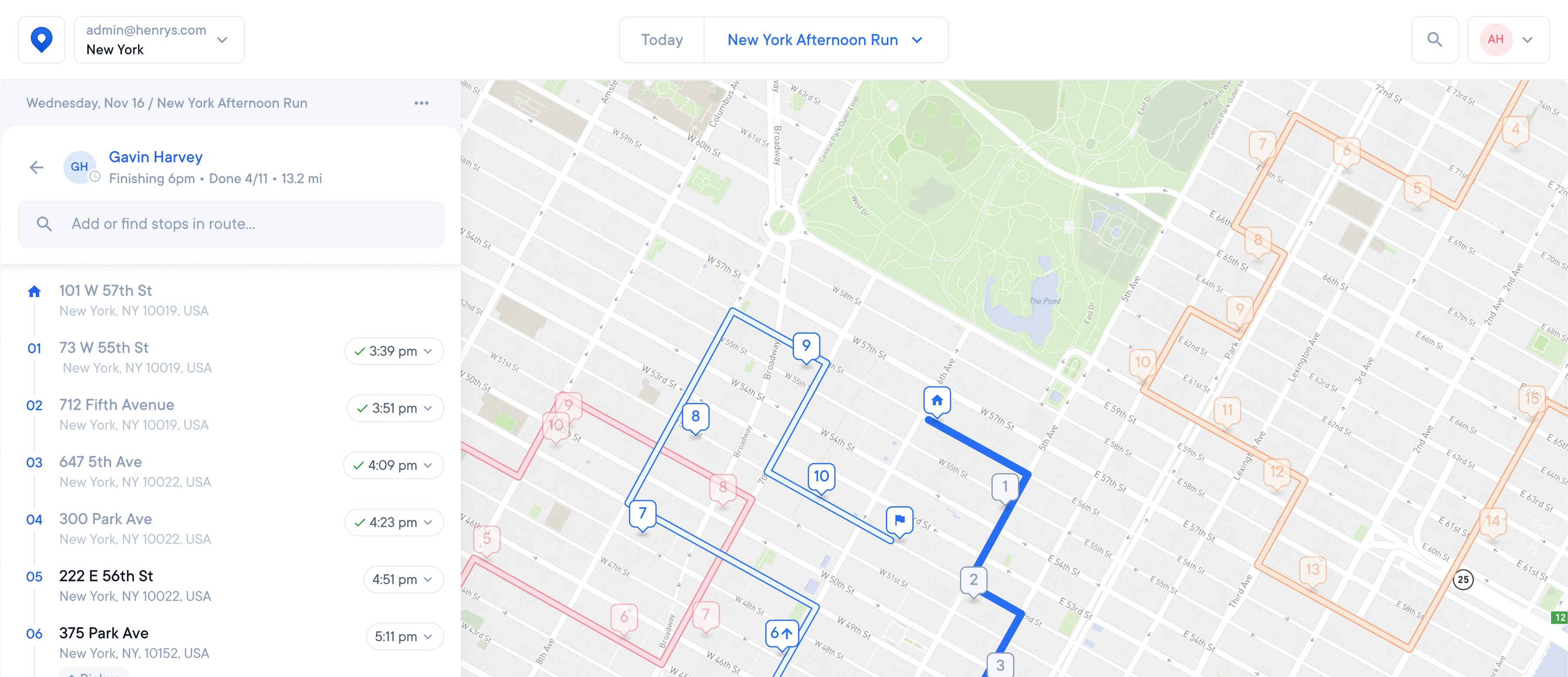

After products leave the warehouse, make sure they get to customers quickly with Circuit for Teams.

If you work in the logistics business as a delivery manager or eCommerce business owner, warehousing is likely a critical part of your operations.

While warehousing has become increasingly important in logistics as eCommerce expands and demand for online goods soars, this has made competition in the warehousing industry fierce, causing rents to skyrocket.

If you’re a manager who deals with warehouse operations, you need to take into account rental fees, maintenance costs, and complicated setup processes.

However, learning the ins and outs of warehousing can help you make smart choices about the type of warehousing you use and how to increase your profits on every sale.

For example, choosing the right warehouse layout and adopting an effective inventory management system can boost efficiency.

Not sure if the extra warehousing costs are worth it?

Keep reading.

I’m breaking down everything you need to know about the role of warehousing in the supply chain. Then explore the main types of warehouses, and detail the advantages of using warehousing.

I’ll also cover the key points that make for an efficient warehouse, so you can use best practices for warehouse logistics in your own delivery business.

What is warehousing?

Warehousing is the process of keeping items in a warehouse.

In other words, it’s physically storing inventory until it’s later distributed or sold to customers.

Warehousing plays the valuable role of storage facility in the material handling process (that is, the way products are kept and moved through the supply chain).

Here are some key traits that set warehouses apart from, say, storage closets:

- Size: Warehouses are large, industrial storage facilities that can span up to one million square feet of space (in fact, these kinds of massive “mega warehouses” are on the rise). That said, smaller warehousing solutions may still be used for micro-fulfillment centers.

- Location: Thanks to their massive size, warehouses tend to be located in suburban areas or city outskirts with room for huge facilities.

- Temporary nature: Warehouses play a temporary role in the supply chain process. They’re for storing goods that are intended to move on and be distributed to customers, not for long-term storage.

The term “warehousing” refers to the general point in the supply chain of storing goods before distributing them.

There are a lot of different processes (and related vocabulary) related to the warehousing process.

To help you out, I’ve added a quick list of essential terms at the end of this guide.

The role of warehousing in the supply chain

The entire supply chain has one goal: Get a product to a consumer.

The final step in the process — when a product actually makes it into a consumer’s hands — is known as last-mile delivery.

Sounds simple, right?

Well, not quite.

Before last-mile delivery can happen, the product must go through a lot of other steps.

For example, let’s say you order a new phone.

Before it gets to you, that phone has to go through a lot of steps:

- Sourcing: Someone must source the raw materials for the phone, like the lithium, cobalt, manganese, and graphite used in lithium-ion batteries.

- Manufacturing: Basic parts need to be refined and manufactured.

- Assembly: Someone assembles the parts.

- Warehousing: A company stores the assembled phone until someone orders it.

- Fulfillment: Someone orders the phone, it’s picked from the warehouse shelves, packaged, and prepared for delivery.

- Last-mile delivery: Someone collects the phone from the warehouse and brings it to the customer.

As you can see, warehousing is only one step in a huge process — but it’s a very important step.

Proper warehousing keeps products safe and secure until customers order them.

If you run an eCommerce shop or a shipping company, warehousing helps bridge the gap in the supply chain process between assembly and fulfillment.

With warehousing storing your products, you can enjoy valuable peace of mind knowing you have inventory that’s ready to ship to customers whenever you need it.

Warehouse vs. distribution center

You might look at the description of a warehouse and think to yourself, “Um, isn’t that a distribution center?”

Well, not quite. There are some differences between the two.

Warehousing is all about storage. A warehouse building isn’t designed with any other process in mind.

In a warehouse, the primary goal is usually to store goods as tightly as possible to maximize warehouse space.

This is especially true as the warehousing market becomes more competitive and people feel the squeeze (fun fact: the US will probably need another one billion square feet of warehouse space by 2025).

In contrast, a distribution center is designed with fulfillment in mind. The goal isn’t just to jam in as many goods as possible.

A distribution center also offers space for processes like picking products, selecting the right product packaging, and choosing shipping labels.

You might prefer a distribution center if you want to keep all your logistics processes in one place.

The distribution center doesn’t just serve as storage — it accommodates goods and fulfillment processes, making it easier and faster to move goods through the supply chain.

That said, some businesses don't want to deal with the effort that comes with overseeing logistics. They may choose to outsource tasks, for example, using a second-party logistics provider (2PL).

This is a courier or shipping service that picks up goods (for example, from a warehouse) and sends them to customers, coordinating shipment, tracking, and delivery.

What are the key functions of warehousing?

I talked about some other steps in the supply chain process and how warehousing fits into the picture.

OK, now bear with me because it’s about to get a little tricky.

Sometimes, a warehouse does double duty and serves other purposes in the supply chain.

Beyond basic storage, warehousing can serve two other key functions: operate as a shipment hub or as an assembly line.

Your warehousing process doesn’t have to serve these two other functions, but it can.

(Whether that makes sense for you depends on your business model and the type of order fulfillment you use.)

Not sure if warehousing is worth the money? Here’s more details on each process and why you may want to choose one over the other..

Warehouses as a regional shipment hub

Some warehouses double as shipment hubs.

A shipment hub receives shipments of goods and holds them until they are distributed to other storage facilities.

For example, let’s say you have warehouses all across North America. These warehouses store goods before last-mile delivery (when your product reaches the customer’s doorstep).

However, suppose your products are imported from China.

To accommodate this, you set up a shipment hub in New York. All your goods make it from China to New York.

From here, they’re distributed to warehouses across the country and sent to customers on demand.

Setting up a shipment hub can streamline supply chain management.

Since you can send your goods to just one easy-access location (like a major harbor or airport), you save time and effort — there’s no need to track and organize the shipment of goods to different points.

Then, from your shipment hub, you can distribute the goods more widely.

You might benefit from a shipment hub if your business deals with foreign imports or exports, you’re trying to expand your geographical reach, or you simply want to consolidate supply chain processes.

Warehouses to assemble or prep products for delivery

When you picture a warehouse, you probably have a mental image of ready-to-ship products lined up on shelves — from computers to toys, clothes, and more.

However, the reality is that warehouses don’t always have finished products.

In some cases, warehouses may double as assembly spaces to put together different product components before they’re shipped to customers (as with our phone example above).

Why would you choose this option?

If you’re selling a product with different parts from many different producers which then need to be assembled.

Instead of investing in a separate space for assembly, you can save money by simply using the warehouse.

For example, let’s say you have a small business that sells statement blouses to retail stores (your customers).

Your blouses are known for their big, bold buttons.

The blouses are shipped from one manufacturer. However, the buttons are shipped from another manufacturer.

You still need to put the two together.

So, you set up an assembly line in your warehouse where workers sew the buttons onto the blouses.

This lets you keep control of your product’s final assembly in-house and saves you money on commercial rent by avoiding the need for an entirely different assembly building.

This also streamlines the supply chain, since finished goods can go directly into warehouse storage to await customer orders.

What are the main types of warehouses?

Not all warehouses are created equal.

Different warehouse facilities can serve different business purposes (there are also different warehouse layouts).

Here’s a quick roundup of the main types of warehouses, plus some pros and cons for each one.

Private warehouses—best for full control

Businesses own private warehouses to store their own goods.

You might opt for a private warehouse if you want to maintain full control of your warehouse operations.

Pros:

- You have total control over the warehouse.

- There’s no need to share warehousing space with other businesses.

Cons:

- Buying or renting your own warehouse can be expensive.

- You have to bear all maintenance costs, like electricity.

Public warehouses—best for small businesses

A public warehouse is owned by a government or state body. You can rent these spaces to store goods for your business.

Pros:

- There’s no need to deal with warehouse management yourself.

- The basic warehouse infrastructure is already set up, so you can start a contract and scale up fast.

Cons:

- You have less control over warehouse operations.

Cooperative warehouses—best for start-ups

Private businesses may come together to establish one shared warehouse to hold all of their various goods. This is known as a cooperative warehouse.

Pros:

- You’ll save money sharing warehouse costs with others.

Cons:

- You have to agree with other businesses on how to manage the warehouse.

- You have to share the warehouse space with others.

Distribution centers—best for fast inventory turnover

Distribution centers focus on short-term storage. They receive goods and move them along the supply chain quickly.

Pros:

- Inventory turnover is fast, so you can get by with smaller warehouses.

- A smaller warehouse is usually cheaper, saving you money.

Cons:

- Managing fast turnover in a distribution center can be complicated.

Advantages of using warehousing

Warehousing is an important part of the supply chain process. It has some serious advantages if you’re a logistics manager, shipping coordinator, or eCommerce platform owner.

Here are some of the reasons warehousing can help grow your business and boost your bottom line:

Protect products

Do you sell perishable, high-value or highly desirable products?

Warehouses help keep goods safe and secure.

A well-designed warehouse will have security systems like locks and CCTV to reduce the risk of product theft. It will also protect against natural threats, like rain, wind, sleet, and snow, keeping products dry and intact.

Some warehouses can also accommodate fragile or sensitive goods. For example, a temperature-controlled warehouse can hold perishable goods needing refrigeration.

Improve capacity planning

Having warehousing handle a big chunk of your supply chain demand is a low-effort method to increasing efficiencies and boosting income.

Capacity planning refers to the process of making sure your business can keep up with supply chain demand.

Warehousing allows you to store large amounts of products in bulk, so you can easily meet consumer demand when orders arrive.

You don’t have to go the extra step of waiting for an order to come in and then securing the product — you’ll have it right there in your warehouse.

Save money

Warehousing can also save your business money in a couple of other ways.

First, warehousing helps prevent theft or damage, which results in products you can’t sell and a loss of potential profits.

Second, warehousing allows you to order wholesale goods in bulk (since you’ll have a big space to store them), which is generally cheaper. It’s easier to negotiate lower prices with suppliers or vendors when you order in bulk.

Reduce overhead costs

Warehousing can also help you save money in other ways.

By setting up warehouses at strategic points across the country, you can shorten delivery distances and cut the transportation costs associated with shipping.

(Psst, this is just one of the many ways to cut transportation costs).

Improve inventory management

Warehousing makes it easy to store, identify, and track inventory.

Why does this matter?

With more accurate inventory control, you can further improve capacity planning, avoid loss, and save money.

You can also create a faster flow of goods and speed up fulfillment with warehouse best practices, like well-planned slotting.

The elements of efficient warehousing

Storage is the primary purpose of warehousing.

That said, a well-run warehouse involves a little more than simply cramming items onto shelves (OK, a LOT more).

Understanding the elements of warehousing can help you make sure your own warehousing operations avoid having a negative impact on your bottom-line.

Here are the highlights:

Receiving

The stuff inside your warehouse has to come from somewhere, right?

Every warehouse should have a designated area for inbound shipments, where goods are delivered to the warehouse.

For example, this might be an unloading bay where trucks can pull in and drop their goods. You also need a process for unpacking, logging, and storing those goods.

Tracking

Once goods are inside your warehouse, you want to track them so you know where to find them again.

You can do this by assigning unique stock-keeping units (SKUs) to products, which you can identify using scannable barcodes.

Warehouse management systems (WMS) allow you to log this data digitally, so you can see where inventory is at any time.

Storage and reorganization

Storage tools like bins and pallets can keep inventory safe.

You also need to make sure you have the technology to safely move goods into and out of storage, such as forklifts. Plus, as new products come in, you may need to reorganize and reorder goods, making these tools even more useful.

Retrieving and shipping

What happens when a customer wants a product that’s in your warehouse?

Someone must retrieve and prepare it for outbound shipping.

You need guidelines for staff to find, pick, and process packages (for example, packaging and loading them).

New technologies and automation robotics might be able to simplify things — for example, if you choose Fulfillment by Amazon, robots will pick packaging for their products.

Security and safety

Effective warehousing focuses on loss prevention.

For example, temperature-controlled warehouses help keep items from spoiling if they need refrigeration.

Security elements like CCTV cameras and warehouse fencing can help minimize the risk of product loss through theft.

With more eyes on your products and a high trust factor, your chances of converting sales increase by simply switching your warehouse operations.

These warehousing best practices can help make your warehouse more efficient and effective. They can even save you money.

For example, warehouse security helps minimize product loss.

If products are lost or stolen, you can’t sell them — which cuts into your profits.

Inventory tracking can also help reduce the risk of losses.

By following the best practices above, your warehouse can be well-organized, run smoothly, and positively impact your profits.

Investing some time, effort, and money in these best practices now will save you headaches later — trust me!

How to get products into a warehouse

So far, I’ve talked mostly about getting products out of a warehouse to consumers. But what about the process of getting products into your warehouse (known as warehouse receiving)?

There are a few best practices that help make this process run smoothly.

First, you want to have a dedicated receiving area where inbound shipments can be delivered. This means you’ll need to accommodate trucks, for example, with loading docks.

Second, you want to identify and label products once they’re unloaded. This helps make sure you get what you actually ordered from the supplier.

Check details like:

- Shipper information

- Purchase order number

- Pallet labels

- Number of pallets

- Product quantity

- Product description

Next, make sure that the goods are properly logged on your side — this helps reduce the risk of product loss.

Technology can help.

For example, you can assign unique number identifiers (SKUs) to product categories for easy tracking.

Scannable barcodes allow you to scan, track, and log products as they move through the warehouse — from the receiving area to the shelves or containers where they’re stored.

These barcodes can be scanned again when items are removed from their slot for shipment.

Finally, have a plan for where and how to move items from receiving to warehouse storage. What tools (such as forklifts) are used to move products and where do certain products go?

For example, high-demand products that move through the warehouse quickly should likely be stored in shelving that’s easy to access.

Warehousing conclusion

Warehousing refers to the process of physically storing inventory before it’s distributed to customers.

It’s an essential step in the supply chain process, bridging the gap between assembly and fulfillment.

Warehousing can help your business in many ways, from protecting products to reducing overhead costs and streamlining operations.

It’s important to follow best practices, like planning inbound shipments and tracking inventory, to make the most of these perks.

Learning about the different types of warehouses, from private to cooperative, can help you find the right model for your needs.

In some cases, warehouses can serve other purposes — for example, they may double as shipment hubs or assembly lines.

For some business owners, this can boost efficiency and cut costs. It just depends on your business model and unique needs.

That said, the biggest objective of a standard warehouse is storage.

This makes it stand out from a distribution center, which is also used for fulfillment processes, like picking and packing products.

Do your due diligence and analyze everything to see if warehousing will make you a profit.

Warehousing glossary

- Backorder: When a certain product or quantity of products isn’t immediately available in the warehouse and an order can't be fulfilled on time. Learn how to manage backorders.

- Batch picking: The process of picking products for shipment in large groups (batches).

- Cold storage: Warehouses with refrigeration. They may hold goods like frozen foods, for example.

- Dry storage: A warehouse holding non-refrigerated or -frozen goods.

- Excess inventory: When a business has more of a product than it needs to meet customer demand.

- Fast pick: High-demand items that move through warehouses quickly.

- First in, first out (FIFO): A process of rotating inventory through a warehouse, using oldest products first. Learn more about FIFO.

- High-density storage: When product loads are stacked more than one unit deep or high.

- Inventory management: The process of making sure inventory is in the right place at the right time in the warehouse to fulfill customer needs.

- Lights-out warehouse: A fully automated warehouse. The logic is that if no humans are needed, no lights are needed.

- Obsolete inventory: Inventory that doesn’t have any use or sales potential for a set period of time.

- Order-as-needed: Inventory you only order on an on-demand basis.

- Pallet: A portable platform holding products that forklifts or pallet jacks can lift, move, and store.

- Public warehouse: A business that offers warehousing to other businesses. Public warehouses usually offer only short-term storage.

- Slot: The physical space in a warehouse where a product is stored.

- Slotting: How products are organized in a warehouse. Slotting aims to optimize product placement, making it faster to find and pick products. Learn more about warehouse slotting.

- Stock-keeping unit (SKU): SKUs are unique identification numbers that are used to identify products in warehouses.

- Warehousing: The physical storage of goods before they’re sent to customers.