Inventory Management 101: Benefits, Methods, and Tips

Manage your inventory all the way to the end customer with Circuit for Teams for last-mile delivery.

Inventory management is essential for any business that buys and sells goods. That’s because inventory management is all about the process of overseeing (or managing) the flow of goods, products, and materials from production to consumption.

Typically, this involves controlling orders, forecasting future demand and stock levels, and managing inventory storage to streamline and optimize efficiency and increase profitability.

For example, a large grocery business might use inventory management to track all that rapid stock turnover. Ultimately, this could improve efficiency by managing resources more effectively.

In this article, we’ll lay out the key benefits that inventory management can offer your business and how you can get the most out of the process.

Key takeaways

- Inventory management can help your business run more efficiently, reduce storage costs, improve customer service, assist with sales forecasting, and increase sales.

- Improving your inventory management process with technology, such as barcoding and mobile apps, can save you time and money with real-time inventory visibility from anywhere in the world.

- With the right inventory management process, you can avoid common inventory mistakes like overstocking, understocking, and inaccurate counts.

- The just-in-time (JIT) inventory method can cut your warehousing and storage costs by reducing the amount of inventory you hold in stock.

- With the first-in, first-out (FIFO) method, you sell the oldest inventory first, allowing perishable items to stay fresh.

- Last-in, first-out (LIFO) inventory management sells your newest inventory first so you can report a higher cost of goods sold, potentially offsetting the impacts of inflation.

What is inventory management, and why is it important?

Benefits of good inventory management

A good inventory management process comes with tons of benefits. Here are some ways the right inventory management system can improve your business outcomes:

- Efficiency. You can increase your business’s efficiency by reducing the time and resources you spend on inventory-related tasks, such as counting, tracking, and ordering. This frees up time for you and your staff to focus on other important tasks. It also reduces the likelihood of errors or discrepancies in inventory records, boosting your efficiency even further.

- Lower cost. Proper inventory management can reduce the costs associated with excess inventory, stockouts, storage, and transportation. That’s because it minimizes excess inventory and unnecessary stockouts.

- Better customer service. Managing inventory means customers get their packages faster. It also reduces the likelihood of their orders going missing or getting damaged in transit, leading to a better customer experience.

- Forecasting. Businesses can improve their forecasting by analyzing past sales data and trends, allowing them to make more informed decisions about inventory levels and replenishment.

- Increased sales. Having the right products in stock at the right time can increase your sales since you can confidently meet customer demand and stock expectations.

Implement inventory management best practices to streamline business processes, improve outcomes and profit, and give yourself more time to focus on other important business matters.

Next, we’ll go into some specific aspects of inventory management and why yours should be as efficient and productive as possible.

What is inventory management, and why is it important?

There are all kinds of inventory management techniques, and each one is tailored to fit the needs of different kinds of businesses.

Choosing the right inventory management methods means carefully considering your business needs. Factors like demand, lead time, inventory value, and ordering costs can help you decide which aspects of inventory management are right for you.

Here are some of the most common types of inventory management that businesses use today. See which one might fit your needs:

Just-in-time (JIT)

The just-in-time (JIT) method involves ordering and getting inventory only when needed to fulfill customer orders or production needs. Its main goal is to reduce the amount of inventory held in stock, reducing warehousing and storage costs.

It works by moving inventory through the supply chain in response to customer demand rather than forecasting.

The main challenge with JIT is that it needs close cooperation with suppliers. You’ll need to make sure your inventory gets delivered on time so you can respond quickly to customer demand for a particular item.

JIT reduces storage costs, also minimizing product obsolescence. For example, if the winter clothes your eCommerce store offers don’t sell before spring, you’re left with obsolete stock you can’t sell.

Using JIT inventory management means you only order the winter clothes your customers want now. This saves the cost of storing goods and avoids leftover stock.

First-in, first-out (FIFO)

Another inventory management method is first-in, first-out, or “FIFO” (not to be confused with FIFA ⚽).

FIFO assumes the first items added to your inventory will be the first ones sold. It’s especially popular among grocery store businesses where the oldest inventory is sold first. This allows perishable items like eggs, yogurt, and milk to stay fresh.

The key benefits of using the FIFO inventory management method: It prevents spoilage and helps you reduce stock obsolescence.

However, you can’t rely solely on how your stock is organized to confirm your products stay fresh. If your business involves selling perishable goods like groceries or pharmaceuticals, you should still manually check your stock periodically to make sure all your stock is safe for customers.

Last-in, first-out (LIFO)

Conversely, last-in, first-out, or “LIFO,” assumes that your most recently added inventory items are the ones you sell first.

Organizations often use this method to manage the impact of inflation on their inventory costs. These businesses may include those in the oil and gas or automotive industries.

Selling the most recently purchased inventory to the end customer before the oldest inventory can allow you to report a higher cost of goods sold, potentially offsetting the impacts of inflation.

The LIFO method might work for your business if your inventory cost is likely to increase in the near future. But this method is only allowed in the US, and you’ll need to find out how it might impact your taxes before implementing it.

Economic order quantity (EOQ)

Economic Order Quantity, or “EOQ,” helps you draw a finer line between ordering too much inventory (which increases your storage costs) and ordering too little (which may prevent you from meeting customer demand).

The EOQ method considers multiple variables, such as the cost of placing an order and holding the inventory and the demand for that inventory over a specific period. It then optimizes the amount of inventory you should order based on these variables.

This lets you keep inventory costs down and minimizes shortages, meaning you won’t have to restock as frequently.

EOQ differs from the JIT method in that it relies on forecasting demand and inventory costs and assumes that these things remain the same over time. So, it requires accurate forecasting.

ABC analysis

ABC analysis is an inventory management method that categorizes your inventory based on its importance and value (basically, how much it sells).

Thai categorization relies on the Pareto principle (also known as the “80/20 rule”) devised by Italian 🇮🇹 economist Vilfredo Pareto. It assumes that 20 percent of your inventory items usually account for 80 percent of your total inventory value.

Pareto came to the idea after realizing that 80 percent of the peas in his garden came from only 20 percent of his pea plants.

You can also apply this analysis to inventory management. The ABC method categorizes inventory into three groups: A, B, and C.

Group A includes the most important and valuable items. It typically represents a small percentage of the total inventory but accounts for a significant proportion of the sales and profits.

Based on the same criteria, Group B includes moderately important and valuable items, while Group C includes the least important and least valuable items.

ABC analysis aims to help businesses focus their inventory management efforts on the most important items (like those in Group A) while minimizing costs and resources for less important items (like those in Groups B and C).

This could be useful for your business if you have a large number of inventory items with different levels of value and importance. For example, the ABC inventory management method could work well for a retail business selling high-value items alongside inventory with less customer demand or a lower profit margin.

Days sales of inventory (DSI)

The days sales of inventory (DSI) method helps you measure your inventory management’s efficiency. It does this by calculating the number of days it takes you to sell inventory since it arrived at your warehouse.

DSI is useful for giving insight into how quickly an item was sold, helping you identify opportunities to improve your inventory and order fulfillment methods.

For instance, a high DSI score might suggest an item is not selling fast enough. This tells you that you may need to adjust pricing for that item or offer a promotion to help it sell.

On the other hand, a low DSI score may tell you that an item is selling too fast. This scenario could lead to stockouts, resulting in lower customer satisfaction and lost sales.

A key benefit of the DSI method is that it helps businesses optimize their inventory management by balancing inventory levels with sales.

This solves the problem of inefficient inventory management through stockouts and low-selling inventory by making the process more efficient, resulting in higher sales and lower storage costs.

Tips for effective inventory management

Mathematical and calculated methods aren’t the only ways to improve your inventory management system. You can establish other methods to keep it running smoothly. Here are some of the best ways to do the job:

Establish a system

Establishing a system to help determine your ideal inventory management system can help you set targets and continually optimize them for the best performance.

For example, setting specific inventory goals — such as reducing holding costs, improving sales velocity, or reducing out-of-stocks — can guide where you and your team need to focus.

This might also help you determine which inventory management method might work best for your business. Inventory management software can also offer some great solutions while automating certain processes, as well.

Conduct audits

Conducting audits helps you stay on top of your inventory and lets you know your inventory management tools are working as needed. This is necessary because there’s still room for error, even though automation can save you lots of time, reduce the risk of human error, and help with inventory accuracy.

The audit method that’s best for you depends on your business needs. For instance, a perpetual inventory audit involves regularly checking inventory levels using inventory management software.

This can work well for a larger business. For small businesses, spot-checking and periodic audits like cycle counting may work for tracking inventory, whether you store finished products or raw materials.

Use technology

Technology is your friend when it comes to improving your inventory management. It can help you automate loathsome tasks and streamline business processes, like calculating your inventory turnover ratio.

For example, inventory management software can automate the process of tracking inventory levels and give real-time visibility into inventory data. This can reduce manual errors and improve inventory accuracy while letting you see your inventory numbers anywhere in the world.

Here are some of the ways technology can streamline inventory management to save time, labor, and cost:

- Barcoding. Barcoding has been around for decades, and it’s still a great way to automate inventory tracking and improve accuracy, speed, and efficiency. Barcodes are often used at the point of sale (POS) in retail and grocery stores to help track sales.

It involves defining stock keeping units (SKUs), creating barcode labels and affixing them to your products, and adding the barcodes and SKUs to your inventory management system. You might also use a handheld barcode scanner to quickly conduct inventory counts and ring up purchases, automatically adjusting your inventory each time.

- Cloud-based software. Cloud-based inventory management software lets you access inventory data and analytics from anywhere, with real-time visibility into inventory levels and sales data. It also keeps IT costs to a minimum since it doesn’t need as much to set up and maintain as other types of software and hardware.

You can choose from many cloud-based, online inventory management software options with various features to suit the needs of any business.

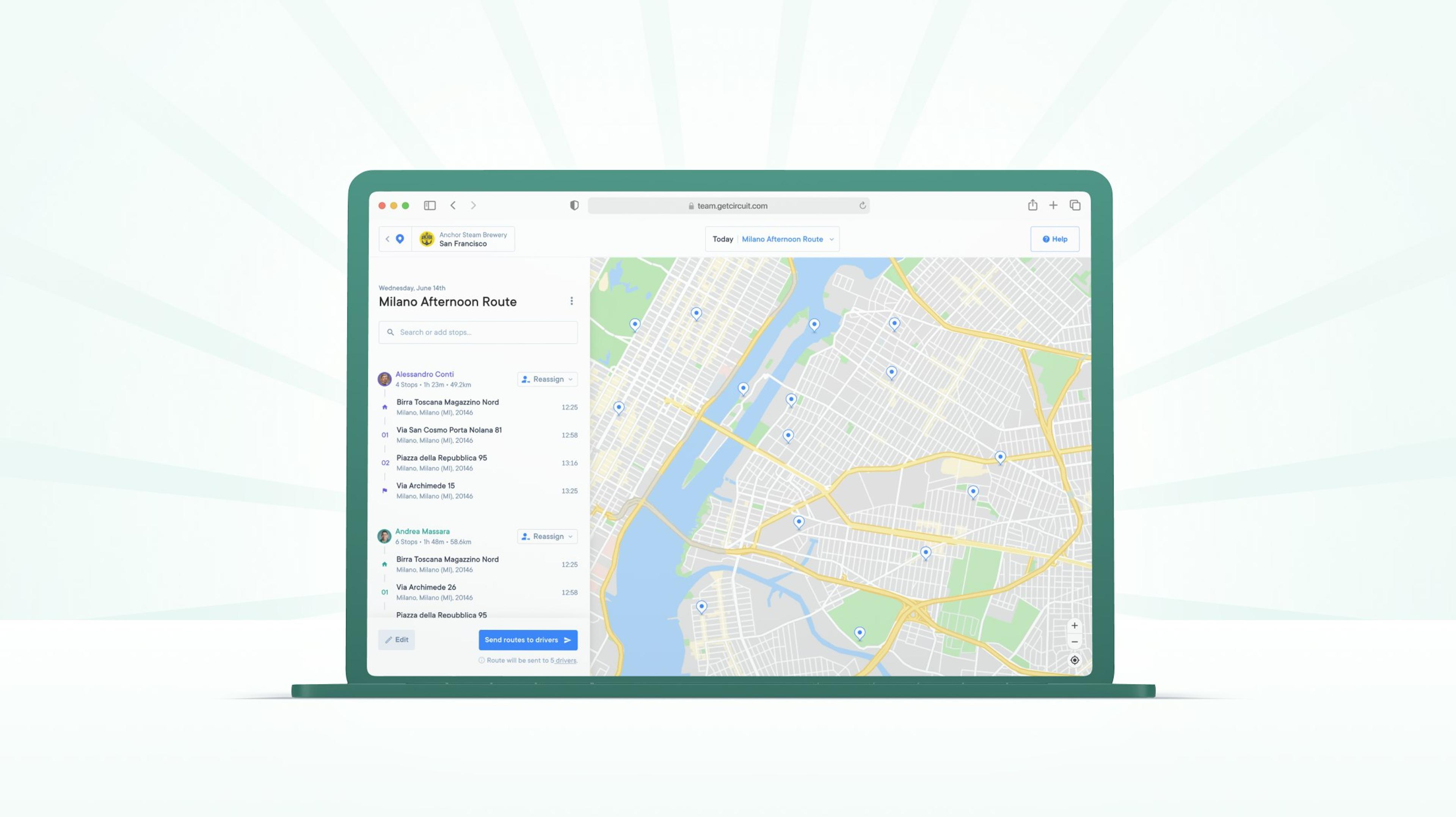

- Mobile applications. Smartphone apps are hardly new, but businesses still forget about these convenient offerings. A mobile app with an intuitive, easy-to-use interface and great functionality can be highly useful for businesses of any kind. Circuit for Teams is a great way to optimize the last-mile delivery aspect of your supply chain.

Monitor your supply chain

Keeping a close eye on your supply chain can reduce the risk of inventory shrinkage and prevent sudden supply chain disruptions.

One way to effectively monitor your supply chain is to frequently check your real-time inventory to make sure it’s at the right level. You’ll also need oversight of your entire operation to spot weak links before they happen.

Here are some ways to do this:

- Use real-time data. You can use inventory management software to capture real-time data on inventory levels, sales data, and customer demand to give visibility into inventory levels. This lets you make proactive decisions for better supply chain management.

- Collaborate with partners. Collaboration with your suppliers, distributors, and other partners can help you optimize inventory levels and reduce costs across your supply chain. You’ll also need to communicate with your suppliers effectively to facilitate this.

- Assess suppliers. Regularly analyzing how well your suppliers are working out for you is another way to make sure your supply chain runs as smoothly as possible.

Occasionally check to make sure they all meet your standards for quality, cost, and service to find out if you should consider sourcing any of your supplies elsewhere.

- Establish key performance indicators (KPIs). Identify and track KPIs related to your supply chain, such as inventory turnover, stockout rate, lead time, and order cycle time. This helps you measure performance and identify any areas needing improvement.

- Forecast demand. Use software and technology to help with demand forecasting. Understanding historical trends can help you gain an edge over the competition and avoid getting caught offhand with out-of-stock items.

- Analyze multiple sales channels. It helps to analyze your multichannel sales to gain a better understanding of your supply chain and customer demand. How are your products performing in different stores? Are they selling better in eCommerce or brick-and-mortar stores?

Determining things like this helps you optimize your supply chain by identifying reorder points: the inventory level at which you need to reorder and replenish your stock.

Train staff

With all this focus on technology, it’s worth remembering that people staff your organization, not robots 🤖. They need proper training for the knowledge and skills necessary to use your inventory management process effectively.

Staff training should cover aspects like inventory tracking, inventory counts, order processing, and storage management, as well as the consequences of inaccurate inventory data and best practices for maintaining inventory levels. Training should also encompass using any necessary inventory software.

Regularly check that employees are up-to-date with any changes to your inventory management systems, workflows, and warehousing needs.

Common inventory management mistakes

Mistakes happen, even in businesses with seemingly airtight inventory management. Let’s go over some of the most common inventory mistakes and how to avoid them.

Overstocking

Overstocking means buying more of an inventory item than you end up needing.

For example, let’s say a grocery store bought 500 cans of lima beans, but customers only bought 100. Those other 400 cans of lima beans are deadstock — and well on their way to spoilage.

The business would have to pay to store those extra lima beans and have less room to store more valuable, high-paying goods. That’s how overstocking reduces cash flow: by tying capital up in finished goods that aren’t selling.

Thankfully, investing in logistics management software can help you keep track of your stock levels and make sure your inventory data is up to date.

Understocking

Understocking can be just as much of a problem as overstocking.

Not having enough stock can send customers to your competitors, reducing overall sales and decreasing customer satisfaction. It may also mean you’re paying for warehouse storage space that you aren’t using, which can also affect your bottom line.

Fortunately, you can avoid this situation through better warehouse management and inventory control. You can also keep some safety stock (or backup inventory) in your warehouse as a buffer to help you meet unexpected demand on short notice.

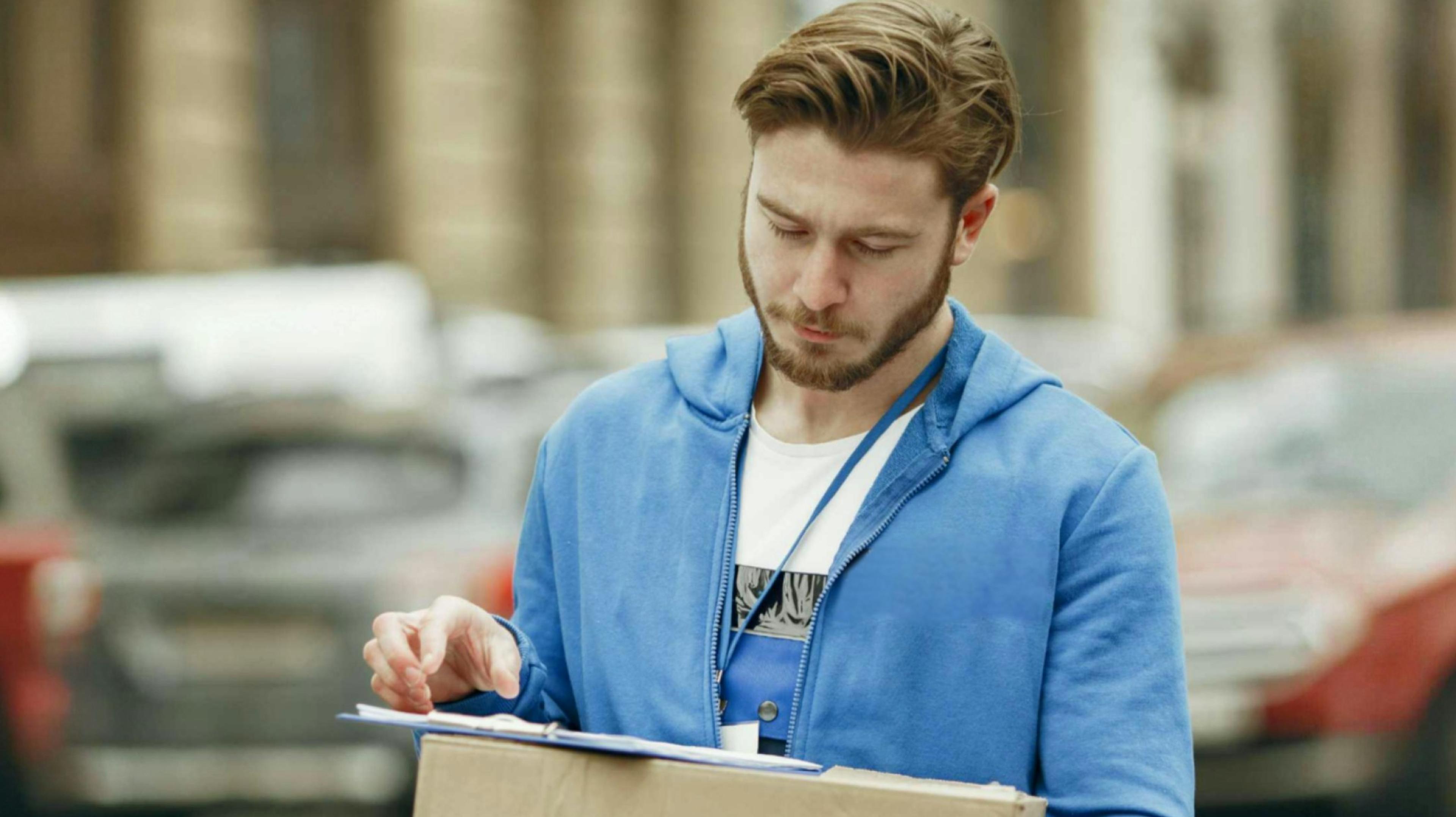

Doing things manually

Manual data entry can cause problems for your business since it can be inaccurate and unreliable.

For example, using a clipboard and pen or spreadsheets to track inventory can result in human error. That’s where technology can help.

Once automated systems are up and running, they’re generally more reliable than staff and only need occasional parameters, software, and KPI updates.

Inaccuracy

Inaccuracy, such as through errors in manual data entry or not knowing how much stock you have left, can be an enormous headache. It increases the risk of problems like stockouts, overstocking, and understocking, costing time, labor, and money to fix.

Most of the problems associated with inaccuracy can be automated away with technology and minimal maintenance.

Managing inventory from end-to-end

With so many things to keep track of, managing inventory can be a challenge. Luckily, the right system and technology can help.

And don’t forget: You also need to track inventory on its way to customers so they get the quality care they deserve.

With Circuit for Teams, you can make sure goods arrive on time with real-time driver tracking information and accurate ETAs, plus the ability to notify customers of any updates. This helps your business stay on top of its game so customers always look to you for the products they need.