How to Calculate the Inventory Turnover Ratio and Why It’s Important

Calculating and tracking your business’s inventory turnover ratio can help you avoid overstocking inventory while making sure you have enough to meet demand. When ready to ship, Circuit for Teams helps you get it to customers quickly.

Inventory management is a big, big job. It’s a bit like the story of “Goldilocks and the Three Bears.”

Basically, you have to make sure that inventory levels are just right so there’s enough product to meet consumer demand without overstocking, which can result in excess inventory taking up space you might not have.

It’s also sometimes hard to unload excess inventory, so you stand to lose money.

You’ve got to strike the right inventory balance between having too much versus too little product.

The key to success? Knowing your inventory turnover ratio.

The inventory turnover ratio is a financial indicator that shows how frequently a company uses and replaces inventory within a set time period.

Figuring out your inventory turnover ratio can help you make smart choices about things like purchasing, pricing, and marketing inventory. With this data, you can make smarter decisions about inventory management.

If you’ve never calculated your inventory turnover ratio, you might be worried that you’re about to deal with complicated financial formulas and complex math. Don’t stress: The formula for figuring out this financial metric is pretty straightforward.

In this article, I’m going to start by explaining what the financial ratio is and why it’s important. Then, I’m going to show you how to apply the inventory turnover ratio formula.

What is the inventory turnover ratio?

Whether you’re new to selling and distributing or have been in the business for some time, you should add inventory turnover ratio to your knowledge bank.

Inventory is any goods that your company plans to sell. Inventory can be anything from unfinished goods (like raw materials) to finished products (like cars, clothing, or toys).

Inventory turnover is how quickly that inventory is sold.

More specifically, it’s the number of days that go by from the day your company purchases the inventory until that same inventory is sold to your customers.

The journey from inventory purchase (beginning inventory) to sale (ending inventory) is considered one complete “inventory turnover.”

The inventory turnover ratio is a precise figure that represents inventory turnover. This benchmark reveals how quickly your company uses and replaces inventory within a predefined time frame.

There’s a formula for calculating the inventory turnover ratio.

While this may seem like a down-in-the-weeds logistics term, assessing the likelihood of how fast your goods will sell can actually change the way you run, optimize, and execute your future operations.

Why is inventory turnover ratio important?

For distributors, the average inventory turnover (and what makes a good inventory turnover) depends on your industry.

It allows you to increase your operational efficiency in a number of ways.

For example, if you sell high-end luxury goods like fancy cars or handbags, you’ll know that they have long production periods, take more time to sell, and generally sell fewer units in a given year.

In contrast, consumer goods like personal care products and foodstuffs have shorter production times, sell quickly, and sell a lot. The demand for these items is inherently higher, contributing to a faster turnover.

But why does inventory turnover ratio matter? Inventory turnover can give valuable information about the health of your business.

For example, you might face decreased consumer demand in the case of low inventory turnover. In contrast, demand might be on the rise in the case of high inventory turnover.

You can use the inventory turnover ratio to make business decisions about things like:

- Pricing: If inventory is selling too slowly (low turnover), is it time to set a discount (like a two-for-one deal)? Alternatively, if your inventory is selling too quickly (high turnover), you might want to raise your prices.

- Marketing: If inventory is moving slowly, do you need to ramp up your marketing? You might put a product in the spotlight, making it more visible to buyers.

- Purchasing: If your inventory is selling too quickly, you may need to increase the number of times you replenish orders. Another option is to find different suppliers. Alternatively, if a product is seeing strong sales, you might stock up on similar products to boost the amount of inventory you have.

How to calculate the inventory turnover ratio

The inventory turnover ratio isn’t a matter of guesswork. You can use a formula to calculate it, giving you an exact number to go by.

It’s pretty simple:

- Take the cost of goods sold (COGS) within a given period

- Divide it by the average inventory within that same period

You’ll have to calculate two numbers to do the inventory turnover calculation: COGS and average inventory.

Average inventory (which you get by adding the beginning inventory and ending inventory and dividing that number by 2) is vital because your company’s inventory can fluctuate throughout the year.

For example, a big-box retailer may stock up on more inventory to accommodate higher sales around a high-volume period of time like Black Friday or Christmas.

The cost of goods sold includes all expenses related to the production of your company’s goods or services. This can include materials costs, labor expenses, utilities, and more.

Inventory turnover ratio example

An example of the inventory turnover ratio calculation in action can make it easier to understand.

Let’s say a company has a COGS of $100 million and an average inventory of $125 million.

Here’s what the inventory turnover formula will look like:

Inventory Turnover Ratio = COGS / Average Inventory= $100,000,00 / $125,000,000= 0.8

In this case, the inventory turnover rate is 0.8 (or 8, for easy reference).

This isn’t a formula that a business calculates once and never looks at again. You must save this data and revisit it regularly.

Keeping a record of your inventory turnover ratios and how they change can help support business decision-making. In the short term, this data can serve immediate decisions like pricing and marketing. In the long term, it can inform decisions like purchasing.

You can also use the inventory turnover ratio for business forecasting, to identify market trends, and more. It’s important to track this data and measure it regularly to see how it changes.

You can use inventory management software to calculate and track your inventory turnover ratio more easily. This also makes it easier to track trends across key accounting periods.

What is a good inventory turnover ratio?

The “perfect” inventory turnover ratio depends on your business.

For example, if you have an e-commerce store selling consumer goods, you’ll likely have a higher inventory turnover ratio than a luxury car dealership.

The key is to make sure that your whole inventory covers customer demands without lingering on shelves (upping storage costs).

But striking a balance between insufficient inventory and overstocking can be tricky.

In general, a result of between 5 and 10 after completing the inventory turnover ratio formula is considered a “good” inventory turnover ratio for most businesses. In the example above, the number 8 is right in that realm.

That said, every industry is unique. The ideal inventory ratio will depend largely on the type of company you have and the products you sell.

Let’s say you’re a business that sells perishable goods, like a grocery store. In this case, a high inventory ratio and fast stock turnover are both important. Otherwise, you’ll lose money when unsold items spoil.

You can cope with a low inventory turnover ratio more easily if your business sells items that don’t spoil.

The best way to determine a “good” inventory turnover ratio for your business is to start tracking it. Once you have a baseline number to work with, you can adapt your inventory control.

Calculating the Inventory Turnover Ratio Conclusion

Inventory isn’t made to sit on the shelves and gather dust. You want to move your inventory fast, making sure it gets to your customers quickly and without any hassle.

By assessing inventory turnover, you gain much clearer visibility into your logistical costs and ways to improve it.

As you start to use this calculation to determine if your goods are moving fast enough, your confidence and comfort with the process will grow.

By incorporating this method into your logistical operations, you’ll also be able to take a more data-backed stance about your cost of sale.

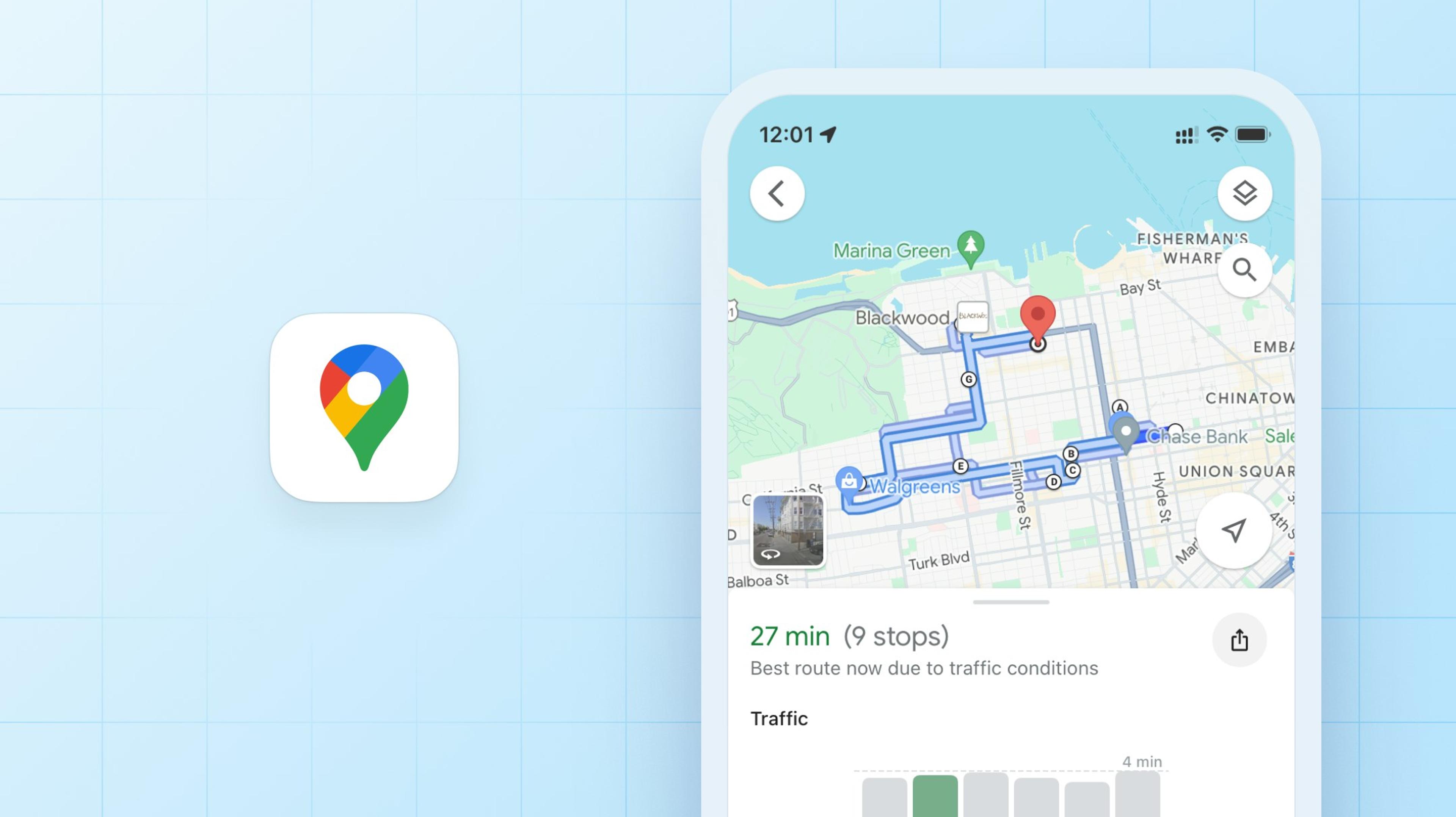

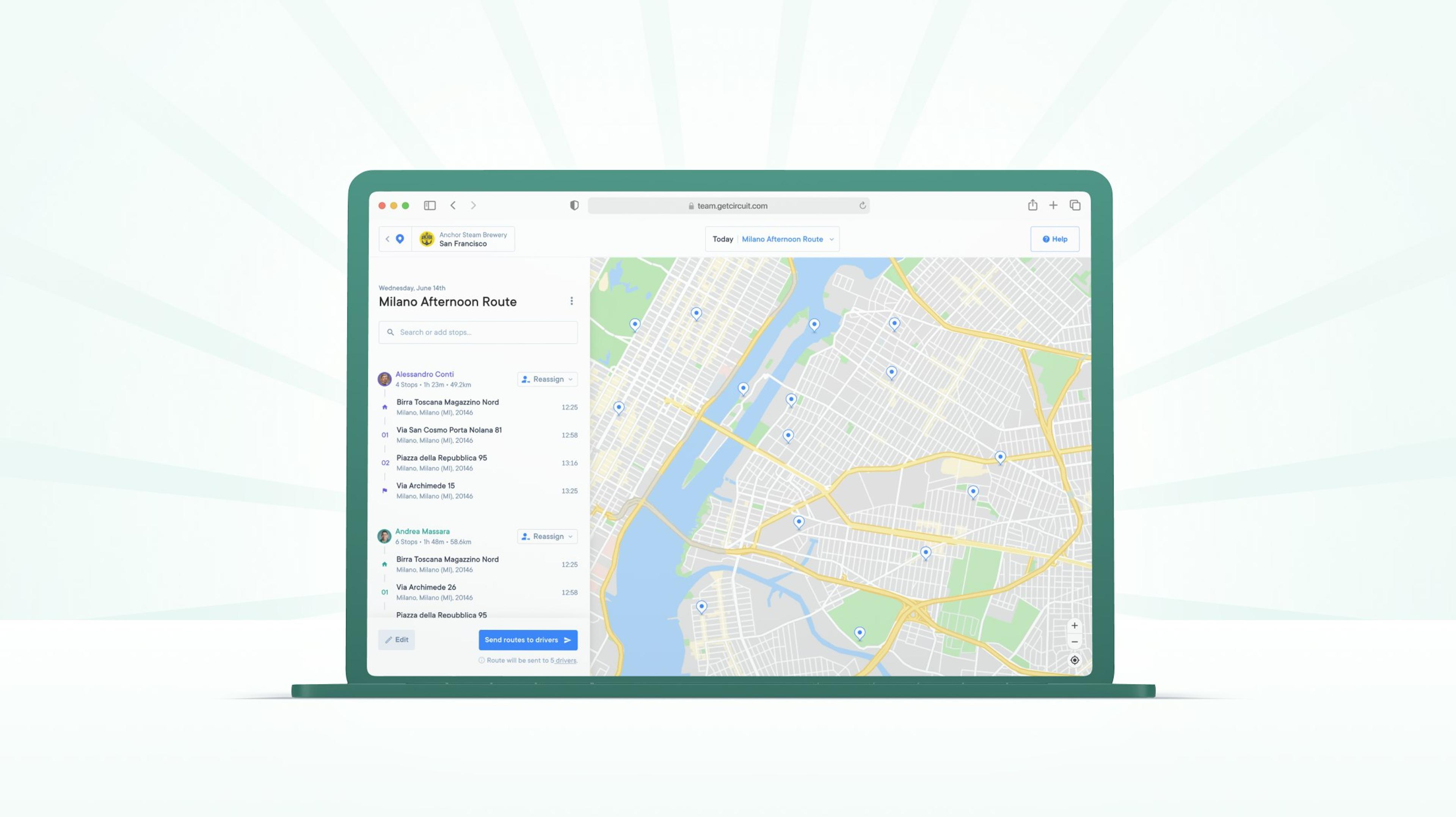

How Circuit for Teams can save you time and money during the shipping process

Circuit for Teams can help save time and money on your shipping process. Our routing software can optimize your last-mile delivery — the final stage in the supply chain responsible for getting products into customers’ hands.

How does Circuit for Teams help improve supply chain management? This cutting-edge software makes optimizing your drivers’ delivery routes fast and easy.

You can upload delivery details, including customers’ names and addresses, into the software tool in bulk using an Excel or CSV file. Circuit for Teams then plans routes for you, setting logical stops for speedy delivery.

By optimizing routes, Circuit can help save drivers time and your company money (in people power, fuel, and vehicle wear and tear). This can cut shipping costs and reduce your overhead expenses, meaning greater profit margins.