What Is a Warehouse Management System (WMS)? Benefits and Types

Easily integrate delivery optimization into your WMS with Circuit for Teams.

A warehouse management system (WMS) acts as the conductor (🚂) of supply chain management — keeping everything in check and helping warehouse operations run smoothly.

In other words, a WMS tracks and optimizes the flow of materials and goods in and out of the warehouse so your warehousing processes are efficient and effective.

This article discusses the wonderful world of WMS, exploring how these systems work, their incredible benefits, the various types of WMS solutions available, and how to choose the best one for your business.

I’ll cover everything from the nitty-gritty of warehouse organization to the fascinating world of eCommerce inventory management.

Ready to learn how the right WMS can help your business flourish?

Grab your forklift (or just a cup of coffee), and let’s get started on this adventure through warehouse management systems.

Key takeaways

- Warehouse management systems (WMS) are software solutions that streamline warehouse operations using mobile devices, scanners, and other tools.

- WMS integrations with ERP, TMS, inventory management systems, and delivery management software create a seamless flow of information. (Don’t worry — we cover those acronyms below.)

- Implementing a WMS and integrating it with Circuit for Teams can help your business optimize its warehouse and delivery processes.

How do warehouse management systems work?

Gone are the days when warehouse workers had to rely on their memory or scribble notes on scraps of paper to track inventory.

A WMS solution helps reduce the need for human input (which can lead to human error), making the entire inventory management process more efficient.

Warehouse management systems (WMS) orchestrate every aspect of warehouse operations to create a harmonious flow in the world of supply chain management.

The WMS takes care of everything from receiving and putaway to order picking, packing, and shipping, so your workers can fulfill orders quickly and accurately.

When an order comes in, the WMS automatically checks product availability so you ship the right products without manual cross-referencing.

Who has time for that anyway?

This saves time and effort and helps your eCommerce business remain competitive in today’s fast-paced market.

That’s the magic of a warehouse management system!

A WMS doesn’t work alone, though.

A WMS solution can make warehouse management run like a well-oiled machine using a combination of software integrations, mobile devices, scanning technology, and other tools.

A WMS often integrates with related systems like your Enterprise Resource Planning (ERP), Transportation Management System (TMS), and Inventory Management System.

This results in a smooth end-to-end process — from warehouse management to last-mile delivery, enhancing overall efficiency and promoting customer satisfaction.

The faster you can get goods to customers, the happier they’ll be.

If you can’t get products to customers fast enough, they might go elsewhere (or worse, take to Twitter and complain). While this isn’t common, it is avoidable.

Now that you have a general idea of how a WMS works, let’s go into the specific processes impacted by warehouse management systems.

Trust us. You’ll be amazed at how much a WMS can make a difference in your warehouse operations.

Processes impacted by warehouse management systems

Today’s latest WMS software solutions do a lot of heavy lifting for warehouse managers.

Here’s a list of some processes a WMS can help with:

- Receiving. A WMS streamlines the receiving process, helping your workers efficiently process and put items away. Radio frequency identification (RFID) technology and barcode scanning can help you automatically receive, validate, and reconcile inventory against digital purchase orders. This makes storage and retrieval a breeze — it’s like having a super-organized friend take care of your inventory.

- Inventory management. Get real-time visibility into inventory across all locations, including items in transit and in stores. A WMS can use barcode or RFID technology, cycle counting, and demand forecasting to help your company adjust inventory levels so you have just enough stock to satisfy demand. This is known as your economic order quantity (EOQ).

- Picking, packing, and order fulfillment. Did you know order picking generally makes up over half of total warehousing costs? A WMS can help lower these costs by optimizing storage, retrieval, and packing. With different picking technologies and techniques, a WMS focuses on efficient order fulfillment so you can focus on growing your business.

- Shipping. A WMS can integrate with transportation management and logistics software to expedite fulfillment, producing shipping documentation automatically and offering real-time tracking. Now you can keep tabs on whether packages arrive on time and at the correct destination, keeping customers satisfied.

- Workforce management. With real-time visibility into warehouse workers, labor costs, response times, and productivity gaps, a WMS allows your managers to react at the right time. Check out our post on workforce management and how it works.

- Yard and dock management. WMS features for yard and dock management can help truck drivers find the right loading docks quickly and support cross-docking for goods handling. This functionality can lead to smooth material handling, getting your products where they need to be without delay.

- Warehouse performance analytics. You can integrate real-time data collected by a WMS with analytics to track crucial metrics, such as on-time shipping, inventory accuracy, and distribution costs. You can then share visual reports with stakeholders, allowing you to make data-driven adjustments to improve warehouse operations.

Next, we’ll explore the six benefits of adopting a WMS.

6 benefits of warehouse management systems

Warehouse management systems (WMS) are the superheroes of the warehouse world, swooping in to save the day and improve your business operations.

These powerful tools offer six key benefits that can transform your business.

Greater efficiency

An effective WMS can increase efficiency within your business or warehouse by automating and streamlining processes from inbound receipts to outbound deliveries.

With these optimized workflows, you can handle higher volumes and get rid of duplicate or unnecessary work.

Plus, WMS systems share real-time data with ERP and TMS, offering you a view that goes beyond your warehouse and accelerates the flow of goods.

Ways an effective WMS can increase efficiency:

- Automate and streamline processes

- Reduce duplicate or unnecessary work

- Optimize workflows for handling higher volumes

- Integrate with ERP and TMS

- Offer real-time data for better decision-making

For example, a clothing warehouse might use a WMS to automatically create pick lists for workers, saving time and preventing errors.

This automation results in the business processing more orders each day — meaning more money in the owner’s pocket (cha-ching).

Improved inventory accuracy

Imagine having X-ray vision to see all your inventory in real time.

A WMS uses barcoding, RFID tagging, sensors, or other tracking methods to offer real-time visibility into your inventory.

This insight helps you come up with precise demand predictions, use a timely inventory approach, and enhance product tracking.

The ability to track your inventory is particularly important when dealing with a recall.

During a recall, you need to know the exact location and quantity of the affected products in your inventory (like, right now).

With a WMS keeping an eye on your inventory, spotting those pesky recalled items is much easier. Then you can quickly remove them from the supply chain and minimize potential harm to your customers (and your bank account).

Ways an effective WMS can improve inventory accuracy:

- Offer real-time inventory tracking

- Help with accurate demand forecasting

- Implement the right inventory strategy

- Enhance traceability for better recall management

For example, a food distributor might use a WMS to keep track of the expiration dates on perishable items.

Having accurate information on each product means the business can make sure workers ship items nearing their expiration date first. This reduces spoilage and waste.

Decreased errors in orders and shipping

An effective WMS can reduce errors in picking and shipping within a business or warehouse.

This precision saves you time and money by reducing the number of returns and customer complaints.

Ways an effective WMS can reduce errors in picking and shipping:

- Promote accurate picking and packing processes

- Automate shipping documentation and labels

- Streamline order management

- Integrate with TMS for better coordination

For example, an electronics warehouse might use a WMS to optimize the order-picking process.

The system can guide employees to the correct items, reducing the number of mispicked products.

This can lead to fewer returns and complaints, increasing customer satisfaction.

Improved customer service

A WMS can enhance customer service by improving order fulfillment, speeding up deliveries, and reducing inaccuracies.

Happy customers mean repeat sales and positive word of mouth — strengthening your brand’s reputation.

Your customers will be singing your praises and coming back for more!

Ways an effective WMS can enhance customer service:

- Speed up order fulfillment and delivery times

- Reduce inaccuracies in shipped orders

- Offer real-time tracking for customers

- Enhance brand reputation through increased customer satisfaction

For example, an online retailer might use a WMS to help streamline the order fulfillment process, so customers get their orders faster.

As a result, the retailer experiences a significant decrease in shipping times.

Who knows? Customers might even take to social media and leave a positive review.

Reduced labor costs

A WMS can help you predict workforce needs, create work schedules, minimize movement within a warehouse, and give appropriate tasks to workers.

The result? A more organized, efficient, and cost-effective operation.

Ways an effective WMS can reduce labor costs:

- Forecast labor needs and create optimized schedules

- Assign tasks to the right employees based on skill level and proximity

- Reduce travel time within the warehouse

- Improve overall warehouse organization and efficiency

For instance, a large warehouse might use a WMS to optimize employee schedules and task assignments.

The system can make sure the business uses its workers efficiently, cutting labor costs and contributing to a healthier bottom line.

Reduced waste

A WMS can help businesses dealing with perishable or date-restricted stock identify which items to pick first or promote to minimize waste (like first in, first out, or FIFO).

It can also help you find the best way to use your warehouse space — from where to put inventory to how to move around.

Some systems even use fancy tricks to make floor plans and put pallets, shelves, and equipment in just the right spots so everything runs smoothly.

All of this WMS intelligence saves time and money, reducing warehouse waste.

Ways an effective WMS can reduce waste:

- Identify items to pick first or promote

- Optimize warehouse space and inventory placement

- Implement advanced simulations for efficient warehouse layout

- Reduce overall operational waste and inefficiencies

For example, a pharmaceutical warehouse might use a WMS to optimize inventory placement and warehouse layout.

They can use the system’s advanced simulations to determine the most efficient placement of shelves and products, reducing the time employees spend traveling between picks.

This optimization can decrease labor costs and minimize product waste by helping warehouse workers pick items with an upcoming expiration date first.

Embrace the power of warehouse management systems to enhance efficiency, improve inventory accuracy, decrease errors, and boost customer service — all while reducing labor costs and waste.

4 types of warehouse management systems

Just like no two warehouse managers have the same needs, there’s no one-size-fits-all WMS for every business.

So, let’s explore the four main types of WMS that cater to businesses of various sizes and needs.

Integrated warehouse management systems

An integrated WMS is ideal for businesses that prefer their ducks (or, in this case, warehouse operations) in a row within a single system.

This type of WMS is usually an add-on to your existing ERP system, which handles invoicing, accounting, and tracking inventory.

Integrated WMS takes care of the warehouse side of things — from order picking and inventory management to shipping and receiving.

With our API features, Circuit for Teams can further enhance this integration by offering robust delivery management and route optimization.

The Circuit for Teams Webhook API lets you connect your Circuit for Teams account to third-party apps, like your WMS.

When something important happens within Circuit for Teams, the Circuit for Teams API will notify your WMS immediately — giving you an end-to-end solution for managing inventory, warehousing, and deliveries.

The beauty of an integrated system is that everything is connected, making it easier to prioritize orders and maximize profits.

Ideal for: Businesses that love integration and want a big-picture view of their operations.

Pros:

- Integration with existing ERP systems

- Streamlined operations and data management

- Better prioritization of orders and tasks

Cons:

- May involve customization to fit specific business needs

- Limited in functionality compared to standalone systems

- Might be expensive due to licensing costs and implementation

Standalone warehouse management systems

Sometimes, you just want something that does one job really well.

That’s what a standalone WMS does.

This feature-rich software focuses solely on warehouse management, offering advanced reporting capabilities that help businesses level up their warehouse game.

A standalone WMS may offer less functionality in accounting or inventory management.

Still, if warehouse management is your top priority, this system might just hit the right note.

Plus, Circuit for Teams can work with standalone WMS solutions when users take advantage of our API. This adds value to your shipping operations by optimizing routes, managing drivers, and offering real-time tracking.

Ideal for: Businesses that prioritize warehouse management and are OK with handling other business aspects separately.

Pros:

- Focused on warehouse management functionality

- Advanced reporting capabilities

- Can be more customizable and adaptable to specific business needs

Cons:

- Lacks integration with other business systems

- May involve additional software for other business aspects

- May not scale well with business growth

On-premise warehouse management systems

There’s something to be said for having complete control, and that’s where on-premise WMS shines.

With an on-premise WMS, you’re responsible for hosting and maintaining your system’s hardware and software.

You can also integrate Circuit for Teams with on-premise WMS solutions using cloud-based delivery management and route optimization that complements your in-house system.

While it comes with a higher upfront cost and the responsibility of regular maintenance, an on-premise WMS offers a sense of ownership and gives you total control over uptime and security.

Ideal for: Smaller businesses that prefer managing everything in-house and don’t mind troubleshooting their own hardware and software.

Pros:

- Total control over hardware and software

- Enhanced security and data privacy

- Customizable to specific business needs

Cons:

- Larger upfront costs

- Involves regular maintenance and updates

- Can be resource-intensive and challenging to scale

Cloud-based warehouse management systems

Delivered as software-as-a-service (SaaS), a cloud-based WMS offers rapid deployment, lower upfront costs, easy scalability, and hassle-free updates managed by the vendor.

With regular updates and maintenance handled by the vendor, it’s like having a dedicated IT team taking care of your system 24/7.

And because cloud-based WMS systems are easy to scale, your WMS can integrate with additional business management solutions as your business grows.

Circuit for Teams is also a cloud-based solution and can integrate with cloud-based WMS systems. This forms a powerful duo that can take care of your warehouse and delivery operations.

Ideal for: Businesses that value flexibility, ease of use, and hassle-free management, so they can focus on operations without worrying about system maintenance.

Pros:

- Lower upfront costs

- Rapid deployment and easy scalability

- Vendor-managed updates and maintenance

- Enhanced accessibility with remote access

- Integration with other cloud-based solutions

Cons:

- Dependence on internet connectivity

- Possible concerns about data privacy and security

- Limited customization compared to on-premise systems

- May have less control over system uptime

- Ongoing subscription fees

So, there you have it — four types of warehouse management systems to help you choose the right solution for your business.

And by integrating Circuit for Teams into your shipping operations, you’ll have a comprehensive solution that covers all aspects of your supply chain.

What’s the best warehouse management system?

Choosing the “best” WMS depends on your specific needs.

For example, a small eCommerce store might need a system that focuses on inventory management, whereas a large-scale manufacturer might prioritize labor management and yard management.

Key considerations when choosing your WMS solution

Keep these factors in mind when picking the ideal WMS for your business:

- Integration. Make sure your chosen WMS plays nicely with your existing software, such as ERP systems, inventory management, and bookkeeping. Integration can help promote warehouse processes and better data visibility.

- Scalability. Your business will grow, and so should your WMS! Look for a system that can adapt and expand as your business does. Scalability features might include add-on modules, like Internet of Things (IoT) integration or allocation management, and the ability to increase inventory volume without breaking a sweat.

- Customization. Every business is unique, so your WMS should be able to cater to your specific needs. Look for software vendors offering customizable features and modules to help you streamline your warehouse processes.

- Support and upgrades. A great WMS should have excellent customer support and regular software upgrades to keep up with the latest industry trends and technologies.

Popular warehouse management systems

Here’s a list of four popular WMS solutions that might solve your warehousing gaps:

NetSuite WMS

The NetSuite Warehouse Management System offers an all-in-one cloud solution for businesses of all sizes.

It helps streamline tasks like receiving, storing, and shipping goods and integrates with ERP, financials, commerce, and more.

Plus, it comes with cool features like mobile RF barcode scanning, task management, and real-time data visibility.

And it has third-party plug-ins!

Fishbowl Inventory

The perfect catch for small to midsize businesses, Fishbowl offers powerful inventory control and manufacturing capabilities.

It integrates with popular business solutions like QuickBooks, Amazon, and Shopify.

Fishbowl’s features include sales and purchasing, order management, multicurrency support, and time and labor management.

The cherry on top? A free trial to test the waters.

Oracle Warehouse Management

Oracle Warehouse Management can transform any site into a well-oiled fulfillment center.

It caters to organizations of all sizes and offers a flexible environment for quick implementation.

Oracle WMS supports manufacturing, distribution, and service industries — offering key advantages like error reduction, improved visibility, better accuracy, and increased customer satisfaction.

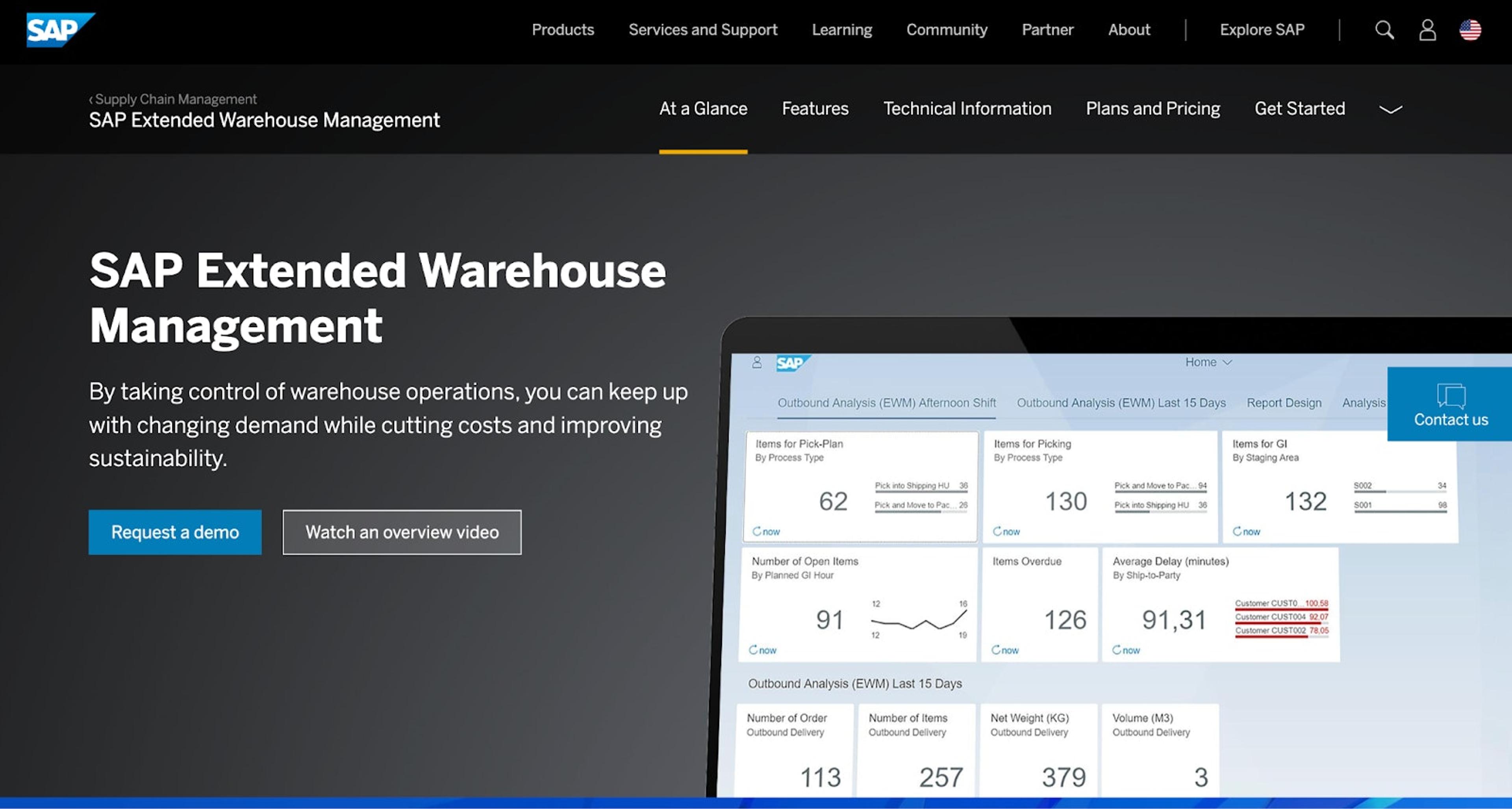

SAP Extended Warehouse Management

A versatile tool that supports multiple warehouse processes, SAP Extended Warehouse Management integrates with external modules like warehouse control units.

It automates resource-intensive processes and uses bin-level inventory management for better warehouse organization and accuracy.

SAP WMS connects with ERP systems to optimize day-to-day logistics, finance, and inventory operations.

Remember, the “best” warehouse management system should cater to your unique warehousing operations and leave you with a better management experience.

Take your time, weigh your options, and choose the WMS that suits you.

Circuit for Teams can optimize your shipping operation

Now that we’ve covered the ins and outs of warehouse management systems, let’s explore in more detail how Circuit for Teams can complement your WMS solution.

With a plethora of nifty features, Circuit for Teams is no joke when it comes to streamlining your shipping operation.

The software is designed for businesses that manage their own delivery operations, drivers, routes, and more.

Key features include:

- Copying stops between routes

- Offering dynamic or fixed delivery windows for customer notifications

- Managing multiple depots

- Integrating with popular eCommerce platforms like Shopify and Zapier

With real-time route editing and dynamic stop status icons, Circuit for Teams minimizes human error and promotes a shipping process that works with your chosen warehouse management software.