What Is a Carrier Facility & How Do They Impact Delivery?

Streamline your delivery management with Circuit for Teams, optimizing every step from the carrier facility to the customer’s doorstep.

As a delivery manager, you’re probably facing another day of complex logistics: Trucks are lined up, drivers are waiting, and customers are expecting their deliveries on time.

In this dynamic environment, the efficiency of carrier facilities directly impacts how you meet delivery schedules and maintain customer satisfaction.

In this high-pressure environment, understanding the role of carrier facilities is crucial. These facilities act as critical intersections in the delivery chain, where packages are received, sorted, and redirected toward their final destinations. The way these facilities operate can determine the speed and reliability of your entire delivery process.

This article guides you through the essential functions of carrier facilities and their impact on delivery management. From their role in streamlining logistics to optimizing customer satisfaction, you’ll gain valuable insights to enhance your operations.

Key takeaways

- Carrier facilities play a vital role in sorting and routing packages for timely delivery.

- The operational efficiency of carrier facilities directly impacts delivery times and customer satisfaction.

- These systems in carrier facilities provide real-time package tracking, enhancing transparency.

- Fulfillment centers, distribution centers, and local courier offices each serve unique roles in the logistics chain.

- Correct sorting at carrier facilities minimizes delays and ensures efficient package delivery.

- Carrier facilities are integral to the success of eCommerce businesses, affecting everything from order processing to final delivery.

What is a carrier facility?

A carrier facility is where packages from online shops and shipping companies get sorted out for their next step in the delivery journey. Think of it as the place where packages get a quick pit-stop, making sure they’re on the right path to you.

At these facilities, the main job is handling the packages that come in, figuring out where they need to go next, and then getting them on their way. This quick and smart sorting is important because it helps make sure deliveries happen on time.

When a package gets to a carrier facility, it gets checked and sorted based on where it’s headed. The goal is to avoid any hold-ups and get each package moving fast to its next stop, whether that’s a nearby delivery office or straight to a customer’s doorstep.

Speed matters a lot, especially for online stores. If a carrier facility is on the ball and processes packages fast, that means quicker delivery for customers. This is a big deal for businesses that promise to deliver customers’ orders the next day or even the same day.

Carrier facilities also help keep an eye on packages. They have systems that update where packages are in real time. This means both the person sending the package and the person waiting for it can always know where it is, adding a bit of peace of mind to the entire process.

So, in a nutshell, carrier facilities are important for making sure packages not only get to customers fast but also let delivery managers track them every step of the way. They’re a big part of making sure the whole delivery process runs smoothly.

Functions of carrier facilities

Carrier facilities play an essential role in the delivery process, with their primary functions being receiving and sorting packages.

Receiving packages

When packages first arrive at a carrier facility, they come from various sources: Some are dropped off directly by customers, while others arrive from collection points.

The first step at the facility is a careful inspection. Staff check each package for any signs of damage or tampering to make sure only intact items are processed further. This includes assessing the packaging’s integrity and ensuring that labels are legible and properly affixed.

This initial stage is crucial in maintaining the quality of the delivery process. Any damage detected at this point can be addressed immediately, preventing potential customer dissatisfaction. Additionally, the efficiency of this stage sets the tone for the subsequent processes in the facility.

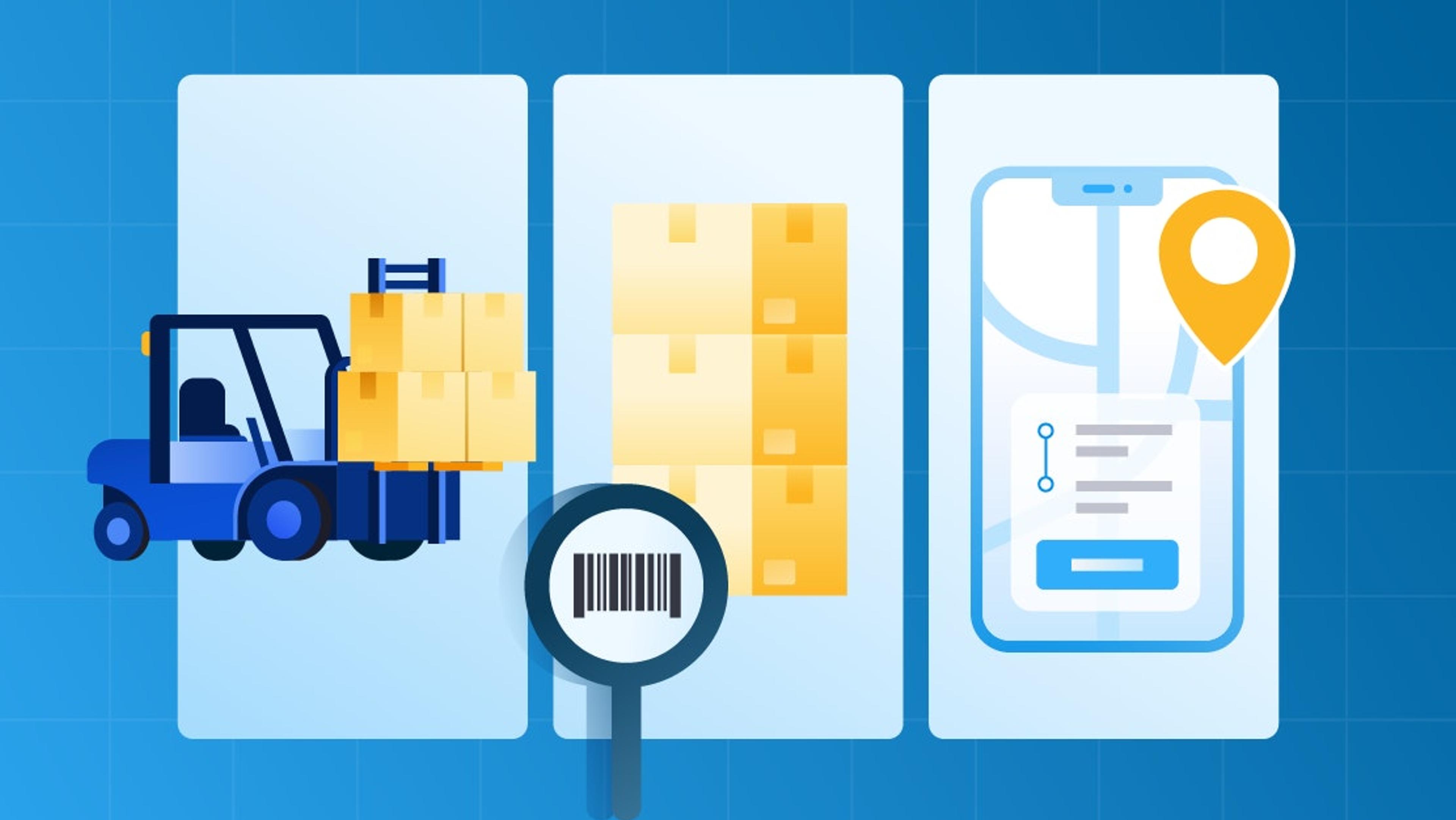

To keep this process efficient, carrier facilities use advanced technology like barcode scanners and automated systems. These high-tech tools help track and record important package information like who’s sending it, where it’s going, and its size, often in real-time.

The use of technology not only speeds up the process but also adds a layer of accuracy and reliability. By digitally capturing and storing package data, facilities create a constant flow of information that aids in the fast and precise movement of packages through the delivery chain.

Sorting packages based on destination

After receiving packages, the next big step is sorting them. This is where sophisticated systems come into play.

Automated conveyor belts, barcode scanners, and computers analyze the data from the receiving stage to sort packages by destination. These automated systems can also identify any special handling requirements, such as fragile items or hazardous materials, and ensure they’re routed accordingly.

Accurate sorting makes sure packages get on the right path to their destinations without unnecessary delays. This is especially important for urgent deliveries, like express or overnight shipping.

Proper sorting also makes the whole transportation process more efficient. By grouping packages going to similar places, carrier facilities can plan better routes, save on fuel, and cut down on emissions.

Impact of carrier facilities on delivery

Carrier facilities have a big impact on the delivery process, significantly enhancing speed, efficiency, tracking, and overall reliability.

Speed and efficiency

Carrier facilities streamline the delivery process, reducing the time it takes for packages to reach their destinations. With their strategic locations and optimized operations, they’re pivotal in minimizing transit times.

Major shipping companies like FedEx, UPS, and Amazon invest in facilities that use automated systems and advanced algorithms for quick, accurate sorting and routing. A great example is Amazon’s network of fulfillment centers, allowing the eCommerce giant to offer fast shipping options like two-day delivery.

These facilities’ proximity to customers and efficient processes are key to their ability to deliver orders quickly.

Tracking and visibility

Tracking is crucial for customers, offering peace of mind and control over their deliveries. Carrier facilities typically use sophisticated systems to offer real-time updates on packages.

Technologies like GPS tracking and barcode scanning allow customers to follow their packages’ journey online. For example, companies like FedEx and UPS provide tracking services, which enhance the customer experience and build trust.

This improved visibility means customers can plan around their deliveries and address issues promptly.

Reliability and accuracy

Carrier facilities focus heavily on quality control to minimize delivery errors. Through package inspections, barcode scanning, and automated sorting, their goal is accurate routing and delivery.

Dedicated teams monitor and resolve potential issues, enhancing the reliability of the service. Quality control measures, such as verifying package contents and following packaging standards, play a big role in accurate delivery.

Consistently reliable service builds customer trust and is essential for businesses, especially in eCommerce, that depend on timely and accurate deliveries.

Scalability and capacity

As online shopping grows, carrier facilities are scaling up to handle increasing package volumes.

They may invest in technology and infrastructure to process and route packages efficiently, even during peak times. Expanding capacity involves building new centers and upgrading existing ones to meet the growing demands.

Collaboration with transportation partners also helps expand their capacity, enabling them to handle larger volumes effectively.

The role of carrier facilities in package delivery

Carrier facilities are key links in the delivery chain. Let’s break down their role and explore how different types of facilities fit into the bigger picture.

Fulfillment center

Fulfillment centers are the starting points in eCommerce order fulfillment. They’re where online orders get picked, packed, and ready for shipping.

These centers are important for making sure customers can get their stuff quickly. Fulfillment centers may use advanced systems to track packages in real time, which helps in speeding up the whole process. This is how they manage to pull off same-day or next-day deliveries. They’re like the kickoff points that set the pace for how fast you get your order.

Distribution center

Next up are distribution centers. These places are all about sorting and getting packages ready for different shipping carriers.

They play a big role in figuring out the best routes for deliveries, which helps in making sure packages don’t get delayed. Distribution centers are like the strategic planners in the delivery world, always working to find the quickest ways to get packages where they need to go.

They also keep track of package statuses, which is key for keeping everyone updated.

Warehouse

Warehouses are the giants in the logistics chain. They store huge amounts of goods for eCommerce businesses. These big storage spaces are essential for managing inventory—basically making sure there’s enough stock to meet customer demands.

Warehouses are crucial for keeping things organized and ready, so when an order comes in, it can be quickly sent to a fulfillment center to start its journey to the customer.

Local courier facility

Finally, we have the local courier offices. These are critical in the last-mile delivery—the final stretch of a package’s journey. They make sure that the packages reach their final destination, usually the customer’s doorstep, efficiently.

Local courier offices are the ones that handle the actual delivery. They’re the last link in the chain, making sure that everything ends well with the package safely in the customer’s hands.

Examples of carrier facilities

Carrier facilities vary widely among major companies like FedEx, USPS, Amazon, and DHL, each with its unique features and operational strategies.

FedEx

FedEx operates an extensive network of distribution centers and warehouses globally. Their facilities are known for their large size and technological sophistication.

FedEx uses advanced automation and real-time tracking systems, enabling efficient package sorting and routing. Their global distribution network is a testament to their capability to handle a range of shipments, from small packages to large freight.

An example of their operational efficiency is the FedEx SuperHub in Memphis, which processes an astonishing half a million packages per hour! And their small package sorting system can automatically sort 320,000 packages per hour.

USPS

The United States Postal Service (USPS), a government agency responsible for mail and package delivery within the United States, operates an extensive network of carrier facilities.

These facilities include post offices, processing centers, and distribution hubs, essential for the efficient sorting, handling, and transportation of mail and packages across the country.

USPS carrier facilities are strategically located to ensure reliable and timely delivery to both urban and rural areas. With its commitment to universal service and affordability, USPS remains a key player in the carrier facilities sector.

Amazon

Amazon, the eCommerce giant, has revolutionized the way we shop and receive goods. With its huge customer base and commitment to fast and efficient delivery, Amazon has built an impressive network of carrier facilities worldwide.

These strategically located facilities, near major population centers, allow Amazon to fulfill its promise of expedited delivery to its customers.

Equipped with advanced technology and automation systems, Amazon’s carrier facilities efficiently handle the high volume of orders.

DHL

DHL’s carrier facilities, including their distribution centers and local courier offices, are tailored for international shipping and express delivery services.

They’re known for their efficient handling of cross-border shipments, with facilities equipped to handle customs and international logistics complexities.

DHL’s express service facilities are designed to rapidly process packages, ensuring timely international deliveries.

Best practices for using carrier facilities

For effective use of carrier facilities in your eCommerce business, shipping company, or logistics operations, consider these best practices:

- Optimize. Choose sturdy and appropriate packaging for your goods, considering dimensions and weight to affect shipping rates and delivery vehicle selection. Use proper protection for fragile items.

- Label accurately. Ensure shipping labels are clear, including essential information like delivery address, tracking number, and special handling instructions. This helps in precise processing and sorting at distribution and fulfillment centers.

- Track efficiently. Implement tracking technology to monitor shipments from the fulfillment center through carrier facilities to the customer’s doorstep. Real-time tracking updates are crucial for managing customer expectations.

- Communicate regularly. Maintain consistent communication with your shipping carrier to resolve issues related to pickups, delivery times, or delays. Effective communication is essential for managing last-mile delivery.

- Leverage technology. Use advanced logistics software for real-time updates on shipments, gaining insights into movements from the warehouse to the final destination.

- Collaborate for custom solutions. Work closely with carrier facilities, like USPS or Amazon facilities, to develop tailored solutions for your specific needs, including arrangements for large warehouse shipments or expedited delivery requirements.

- Understand carrier strengths. Recognize the unique strengths of different carriers, such as FedEx’s global network or DHL’s international shipping expertise, to choose the right carrier for various deliveries.

- Adapt to seasonal volumes. Prepare for peak seasons by adjusting inventory levels at distribution centers and collaborating with carriers to anticipate increased demand.

- Gather feedback. Regularly collect feedback from customers and carriers, using this information to continually improve logistics processes from order fulfillment to final delivery.

How Circuit for Teams enhances the use of carrier facilities

Circuit for Teams is a powerful tool that can optimize how your business uses carrier facilities. We explain how integrating Circuit for Teams can make a difference:

Efficient route management

Circuit for Teams simplifies managing multiple delivery routes, which is crucial for businesses with fleets of delivery trucks and vans. This helps in reducing time spent on planning and optimizing delivery times from distribution centers to the customer’s doorstep.

Real-time tracking and ETA accuracy

The platform provides real-time tracking of delivery vehicles, offering accurate estimated times of arrival (ETAs). This feature is essential for keeping track of packages en route, ensuring timely updates from the carrier facility to the final destination

Improved customer communication

With Circuit for Teams, businesses can keep customers informed with real-time updates via email and SMS, enhancing transparency from the fulfillment center to the final delivery.

Driver time savings

By optimizing the fastest routes for delivery vans and trucks, the tool saves hours for drivers, making the process of order fulfillment and final delivery more efficient.

Using Circuit for Teams can optimize the use of various carrier facilities, enhancing the overall efficiency and effectiveness of the delivery process from large warehouses and distribution centers to local courier offices and the customer’s doorstep.

Carrier facility FAQ

To help clarify some common questions, here’s a FAQ section that addresses key aspects of carrier facilities.

What does “package has left the carrier facility” mean?

When you see “package has left the carrier facility” in your tracking information, it means your package has finished processing at a particular facility and is now on its way to the next stage in its delivery journey. This could be another sorting center, a distribution center, or directly en route to the final destination.

What does “package arrived at a carrier facility mean”?

“Package arrived at a carrier facility” indicates that your shipment has reached a specific facility in the delivery network. This is a step in the process where the package is sorted, possibly stored temporarily, and then prepared for the next leg of its journey, which could be to another facility or toward its final delivery address.

What is a local carrier facility?

A local carrier facility is typically the last stop for a package before it reaches its final destination. These are smaller, local hubs (often linked to specific carriers like USPS, FedEx, or UPS) where packages are sorted for final delivery.

From these facilities, packages are loaded onto delivery trucks or vans for the last-mile delivery, ultimately reaching the customer’s doorstep.

Keep track of packages with Circuit for Teams

Understanding the various aspects of carrier facilities, from their roles in the eCommerce fulfillment process to best practices for using them, is essential for businesses in today’s fast-paced delivery environment.

Using tools like Circuit for Teams can further streamline these processes, offering enhanced tracking, efficient route planning, and improved customer communication.

By embracing these technologies and strategies, your business can ensure efficient, timely deliveries and high customer satisfaction.

Ready to transform your delivery management? Sign up for Circuit for Teams and take the first step toward optimized logistics.